Chopper's

Foot Drive

Structural

Assembly

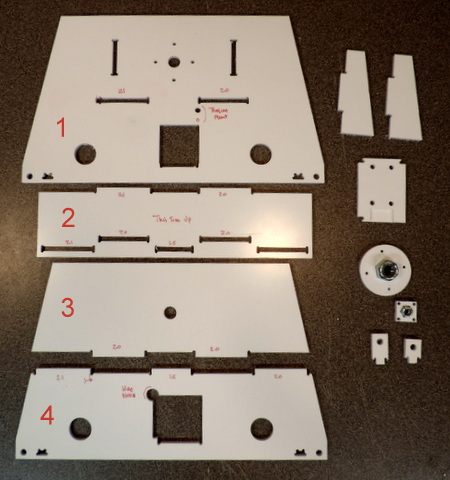

Parts Preparation

In addition to the normal parts preparation for CNC cut parts (removing

flash and tabs from the parts that have been removed from the panels)

there are a couple of suggestions that apply to Structural Asssemblies

as well as suggestions that might make the prep easier for specific

parts. We'll cover that first.

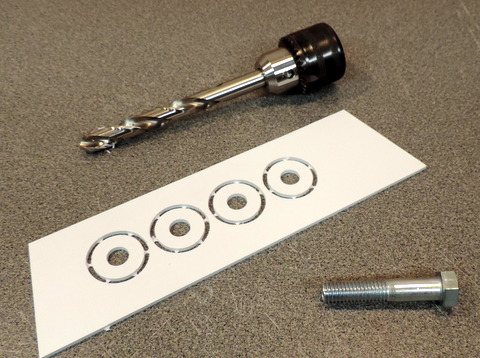

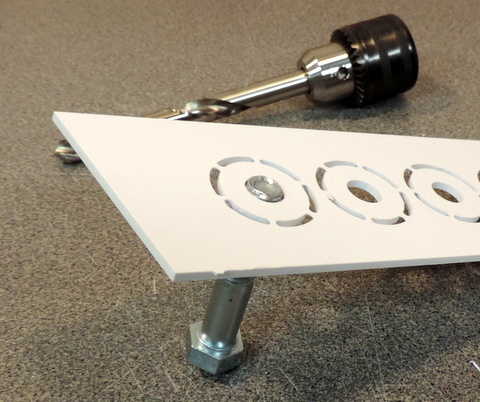

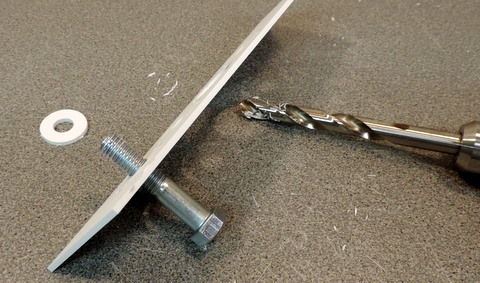

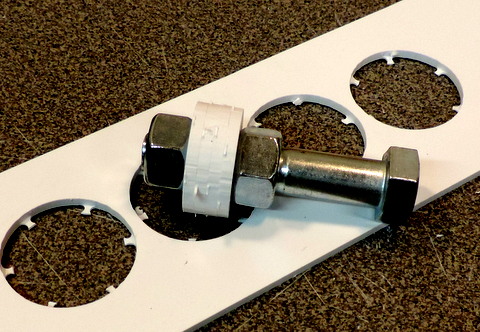

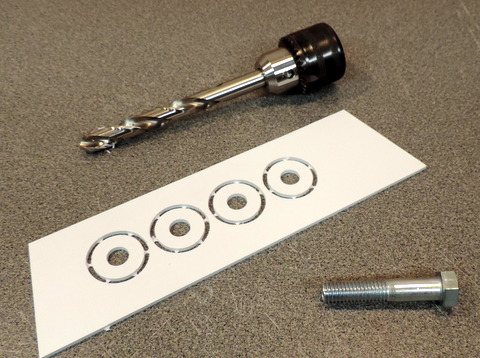

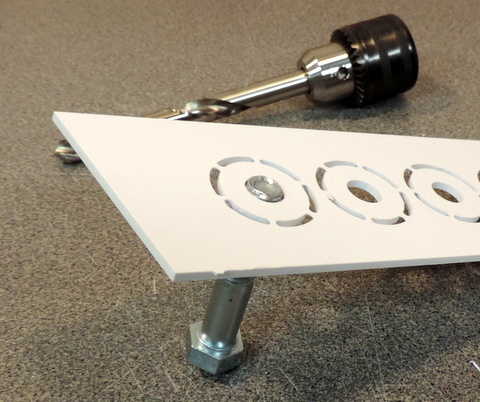

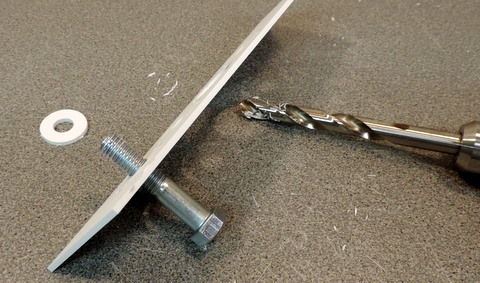

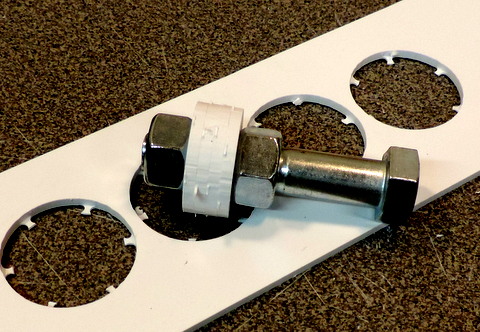

Above

& Left: These are the ??? spacers. One problem is that even

though they have been cut for a 1/2 in bolt the bolt doesn't fit !

|

|

I

enlarged the holes by hand using a drill - do that while the parts are

still in the panel. It's easier than trying to hold the parts with tabs

that might cut your fingers.

|

|

|

|

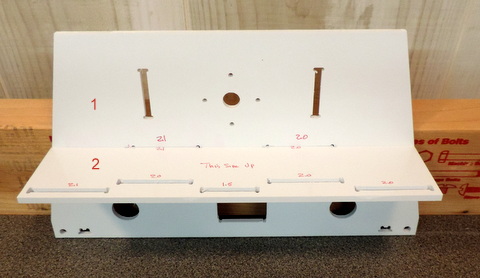

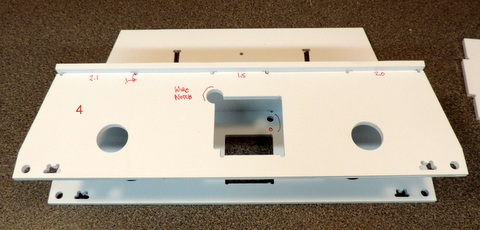

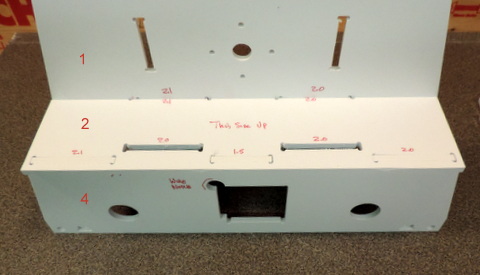

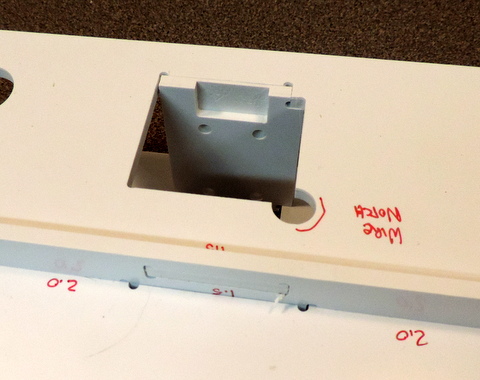

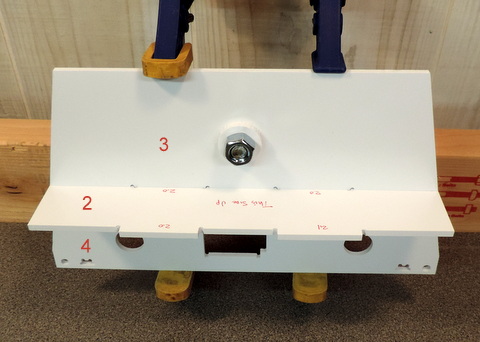

Dry Fit

In

the steps that follow we'll verify the fit of the parts by assembling

but NOT gluing the parts. This is a structural assembly (meaning it's

weight and load bearing) so a tight fit is necessary. The slots are cut

to fit .1875 tabs (the nominal thickness of the styrene sheets).

Unfortunately, not all sheets measure exactly .1875 - the ones I got

for this panel run measured .188. That's just enough to make if

difficult to insert the tabs into the slots. DO NOT try to hammer the

parts together. That causes micro cracks at the corners, When you apply

solvent to the parts the cracks expand and propogate. Instead, file the

slots JUT ENOUGH to get a tight fit and NO MORE. File a little, check

fit, file some more. We are relying on slovent welding for strength.

Tight joints are part of the process.

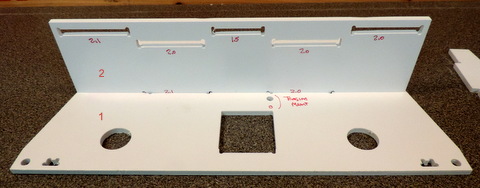

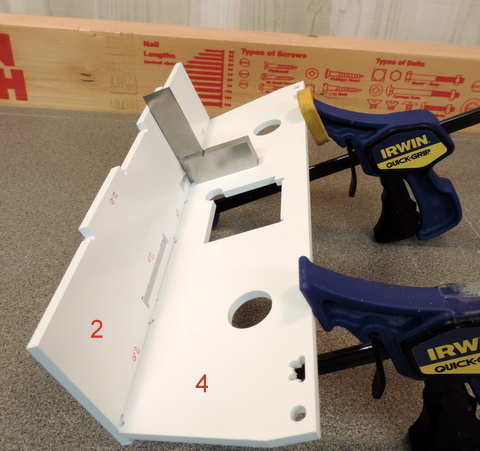

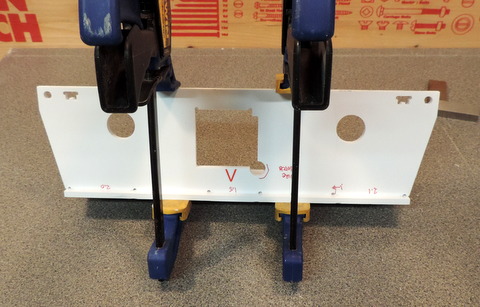

Assembly & Glue Up

In

the steps that follow we'll re-assemble the parts, naturally in a

slightly different order to enable easier clamping. We'll also apply

solvent to BOTH SIDES of the joint being assembled. WAIT for the

solvent to dry on the first side before going on to the second side.

This design is

copyright Media-Conversions LLC and is made available for non-commercial

use only.

Chopper

Home Page